company

facts History mission

company history

The company KEAM s.r.o. was founded by Ing. Peter Havlík in 2012 after several years of business as self employed.

The company operates in the field of custom engineering manufacturing and design of fixtures, tools and single-purpose machines. Sale and distribution of CAD/CAM software is also a part of our activity

Investing in state-of-the-art technology is a way to stay competitive in the market and meet all customer requirements.

What they wrote About us

Custom made robotic cell with laser head from Slovakia

We have very talented users who not only use off-the-shelf robotic cells, but also customize them. And SprutCAM X Robot helps them with programming.

Our reseller from Slovakia – KEAM s.r.o, shared information on one of these customers.

Robot is programmed with SprutCAM X Robot, and has a custom post processor for laser head. Laser head is LED laser, 30W optic power, the customer is using it for etching and engraving stainless steel and aluminum parts. At the time, the robot is equipped with a quick change system, which allows it to change the laser head to any other actuator only with releasing one lever.

Innovation of production moves the KEAM company to a "higher level"

Mechanical engineering represents the permanent passion of Petr Havlík, the founder of KEAM. He started as an employee, later became a self-employed person, and today he manages a company that constantly modernizes its machine park in order to offer attractive options for its regular and new customers. They also take exceptional care of their employees, supporting them in their ability to operate all machines, which ultimately contributes to greater flexibility and efficiency.

Get to know our company in the Tatra banka article.

PLANNED INVESTMENT IN NEW production HALL

Since 2012, we have gradually invested in expanding our machine park. We have secured new, modern high-quality technologies that help to create high-quality, valuable and durable parts in production.

The planned investment in the new production hall is the culmination of the efforts of the entire team in our company, which we see as an investment in the future of KEAM s.r.o..

our machine PARK

Since 2012, we have regularly invested in expanding our machine park. With this, we ensured an increase in production capacity for our partners. New modern technologies ensure the production needs of our design office as well as small series custom production.

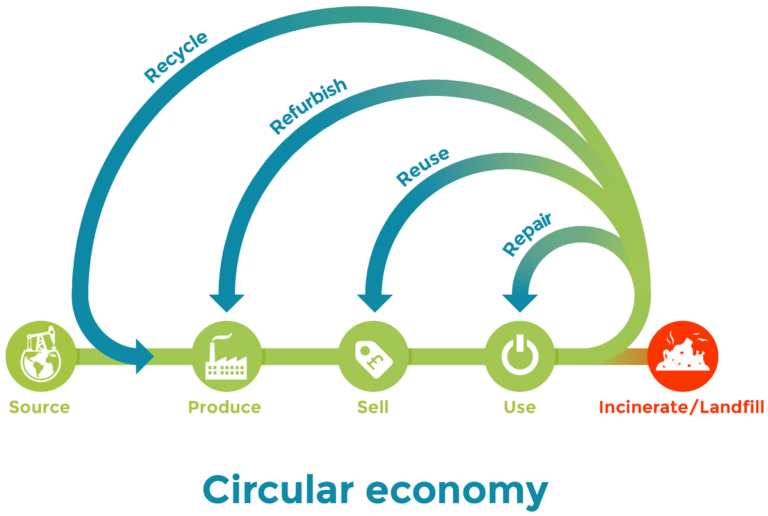

We support a circular economy

The circular, circulation economy has recently been moving the world.

Industry is known to ensure prosperity throughout Europe. However, at the same time, large industrial units directly or indirectly increase CO2 emissions. The company KEAM s.r.o. realizes that it can reduce CO2 emissions in a small amount.

The solutions that we find directly in the production process ensure for our partners the reuse of their production tools and, after restoration, their inclusion back into production. By which we reduce their overhead costs for our own production and at the same time protect our planet.

KEAM s.r.o. subscribes to this commitment.

We recycle and protect nature

The company KEAM s.r.o. long-term sorting of waste generated in operation. Recycling and reuse of waste materials is deeply rooted in the mission of our company. According to the type, our sorted waste is taken away by our partners, who ensure its reuse.

WE PROTECT YOUR DATA gdpr